A Guide to Understanding the Different Types of Defoamers Available

A Guide to Understanding the Different Types of Defoamers Available

Blog Article

Picking the Right Defoamer for Your Particular Application Demands

Selecting the suitable defoamer for particular application needs is a nuanced procedure that requires careful consideration of multiple elements, such as the foam operating, kind, and tool problems. Comprehending the subtleties of defoamer efficiency-- including rate and persistence-- while likewise accounting for ecological and governing aspects is essential.

Understanding Foam Development

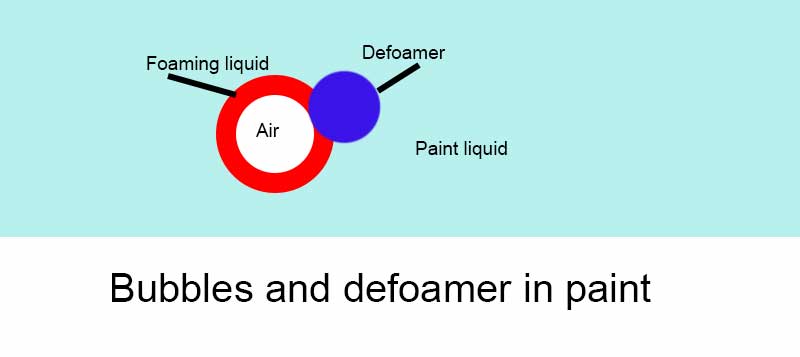

Foam formation takes place when gas is trapped within a fluid, developing a stable structure of bubbles. This sensation can significantly impact numerous industrial processes, particularly in industries such as food manufacturing, pharmaceuticals, and wastewater treatment. The existence of foam can hinder mixing, decrease product quality, and even lead to functional ineffectiveness.

Foam typically develops as a result of a mix of aspects, including surface-active representatives, anxiety, and the qualities of the fluid stage. Surfactants reduced the surface tension of the fluid, facilitating the development of bubbles that can coalesce and maintain. Anxiety, whether from mechanical stirring or gas introduction, improves bubble formation, leading to raised foam volume.

Recognizing the mechanics of foam development is vital for markets aiming to optimize their processes. By identifying the details conditions that promote foam generation, organizations can apply methods to alleviate its effects.

Sorts Of Defoamers Available

Various kinds of defoamers are offered to attend to the difficulties postured by foam in industrial applications. defoamers. Broadly categorized, defoamers fall right into three classifications: silicone-based, non-silicone-based, and natural defoamers

Silicone-based defoamers are renowned for their efficiency and security across a vast array of temperature levels and pH levels. They are generally used in applications where strong foam suppression is essential, such as in paints, adhesives, and finishes. Their low surface area stress enables rapid foam collapse.

Non-silicone-based defoamers, typically made from natural compounds, use an alternative for applications delicate to silicone deposits. These defoamers can be more split right into polyether and ester kinds, each customized to meet certain solution needs. Non-silicone defoamers are frequently utilized in food handling and individual treatment products because of their compatibility with various solutions.

Natural defoamers, originated from plant or animal resources, are acquiring grip because of their environmentally friendly profile. These products are especially appealing in applications where governing conformity and sustainability are critical, such as in agrochemicals and biotechnology.

Choosing the best sort of defoamer is critical for maximizing performance and making certain compatibility with specific applications.

Trick Application Factors To Consider

When selecting a defoamer, it is vital to think about the specific application needs to make certain optimal efficiency. defoamers. Different industries have unique demands, such as food handling, drugs, or wastewater therapy, and each application may require one-of-a-kind defoaming residential or commercial properties

Trick factors to examine consist of the medium in which the defoamer will be made use of, whether it is water-based, oil-based, or a mix thereof. The temperature and pH degrees of the application can also substantially influence the effectiveness of a defoamer. Additionally, compatibility with other chemicals present in the system is important to avoid unfavorable responses that might compromise performance.

One more essential consideration is the lathering actions of the certain system. Comprehending whether the foam develops promptly or slowly can guide the selection of a defoamer that targets the origin successfully. The desired rate of defoaming can influence the choice, as visit our website some applications call for quick activity while others might tolerate slower defoaming processes.

Last but not least, regulatory and environmental factors to consider need to not be ignored, especially in industries with stringent conformity needs. Selecting a defoamer that aligns with these aspects makes certain both efficiency and security in the application.

Efficiency Testing Techniques

Assessing the performance of a defoamer requires an organized technique to screening that precisely measures its performance in details applications. Numerous efficiency screening techniques can be utilized to ascertain the optimum defoamer for a provided formula.

One common technique is the bubble test, which reviews the defoamer's capability to reduce foam volume over time. This examination involves producing a stable foam and after that including the defoamer to observe the rate of foam collapse.

Ultimately, choosing the ideal performance screening technique depends upon the certain application and the kind of foam being attended to. Each technique provides valuable information that can guide formula adjustments and enhance the performance of the defoamer in useful applications.

Finest Practices for Choice

Following, take into consideration the defoamer's efficiency in regards to speed of activity and perseverance. A quick-acting defoamer may be required for procedures where rapid foam suppression is important, while an extra persistent formula could be required for long term foam control. In addition, review the ecological influence of the defoamer, including its biodegradability and any kind of governing conformity demands.

Conduct trials with picked defoamers to identify their effectiveness in real-world problems. By adhering to these ideal practices, you can boost foam control effectiveness and ensure the long life of your processes.

Verdict

In summary, choosing the appropriate defoamer requires a detailed analysis of various elements, consisting of foam kind, tool, operating problems, and ecological considerations. Understanding the distinct qualities of foam development and the offered defoamer alternatives is critical.

Picking the appropriate defoamer for click now specific application check my site needs is a nuanced process that demands careful consideration of several factors, such as the foam tool, operating, and kind conditions.Selecting the appropriate defoamer is essential for accomplishing ideal performance in foam control applications. A quick-acting defoamer may be required for procedures where fast foam suppression is vital, while a much more consistent formulation might be needed for prolonged foam control.In recap, choosing the ideal defoamer demands a detailed examination of different elements, including foam type, tool, operating conditions, and ecological factors to consider. Recognizing the special attributes of foam formation and the readily available defoamer alternatives is critical.

Report this page